On the morning of February 22, Yulin's first N95 mask production line was put into pilot production. From investigation, procurement, installation, commissioning and delivery of equipment for production and use, Guangxi Watyuan Filtration System Co., Ltd. ("Watyuan") took only 12 days, nearly 30 days shorter than the normal equipment procurement and delivery cycle, highlighting the "hard core" of Watyuan.

On February 10, in consideration of the severe epidemic situation and the shortage of masks in the market, the People's Government of Yulin decided to pool resources to build Yulin's first N95 mask production line as fast as possible. Watyuan, by virtue of its own resource advantages in the filtration industry, took the initiative to purchase equipment and raw materials for the production of N95 masks, and Dashenlin Pharmaceutical Group Co., Ltd. ("Dashenlin") which already has a medical mask production site undertook the production work.

On February 11, Watyuan rushed to the manufactories in Shenzhen and Dongguan to follow up the mask equipment manufacturing on site, and completed equipment acceptance on February 18. At 5:00 p.m. on February 19, the production equipment arrived at Yulin Traditional Chinese Medicine Health Industrial Park a day earlier than expected. Upon the arrival of the equipment, Watyuan immediately started pre-inspection of the equipment.

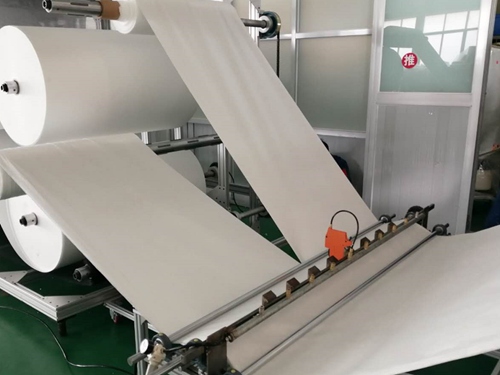

On the morning of February 20, the disinfected mask production equipment was delivered to the production workshop with the cleanliness class of 100,000 at Yulin Base of Guangxi Branch of Dashenlin. Cheng Kenu, Watyuan's Senior Manufacturing Engineer in charge, immediately started commissioning of the equipment. "The whole production line is mainly composed of five apparatuses with different functions. Masks are produced mainly in 5 steps: cutting, ultrasonic welding, locating of welding points, sealing welding and welding of ear loops", Cheng Kenu said. Owing to familiarity with the technology and smooth equipment commissioning, the production equipment was delivered for the production of N95 masks on the morning of February 22. Watyuan completed the procurement of raw materials and made special dividing and cutting machines for dividing and cutting filter materials in advance, thus ensuring the pilot production of the N95 mask production line.

According to the head of Dashenlin, Dashenlin would produce 4,000-5,000 N95 masks a day as expected and deliver these masks to all medical institutions in Yulin in the shortest time.

(Huang Jingru)