As of the end of January, the Yuchai tractor engine market has seen a year-on-year increase of 383% in total received orders, with gas engine orders specifically soaring by 1673%, making a good start. This growth was driven by the mature, stable, and cost-effective K13N gas engines and the K14N and K15N newly launched in batches.

After nearly a year of meticulous R&D and road testing, Yuchai K14N and K15N products have been launched in batches. Let's see which vehicle brands are equipped with the two Yuchai engines.

On January 12, Dongfeng Trucks Xinjiang D7V + Yuchai K14N engine and Dongfeng Trucks Xinjiang X7 + Yuchai K15N engine were put on the market in batches and shipped to provinces with high demand for gas vehicles such as Shanxi, Henan, Sichuan, Ningxia, Hebei, and Shaanxi.

On January 20, Qingdao Jiefang JH6 + Yuchai K15N engine was put on the market after undergoing the second round of vehicle production, signifying the completion of the mass production process for this vehicle model and the qualification for vehicle mass production.

On January 26, Dongfeng Liuzhou Motor H7+ Yuchai K15N engine entered the market in batches. It will be shipped to Guangxi, Shandong, Shanxi, Hebei, Sichuan, and other regions.

On January 29, Shaanxi Automobile Holding Group Commercial Vehicles Deyu Q300+ Yuchai K14N engine entered the market in batches. It will be delivered to customers in Shanxi, Ningxia, Shaanxi, Inner Mongolia, and other regions.

Furthermore, Foton Daimler GTL + K15N and K14N engines, Dongfeng Trucks KX/KL + K15N/K14N engine, C&C Trucks U + K15N engine, Shanxi Dayun N9H + K15N engine, and other brand tractors are set to enter the market gradually in the first quarter of this year.

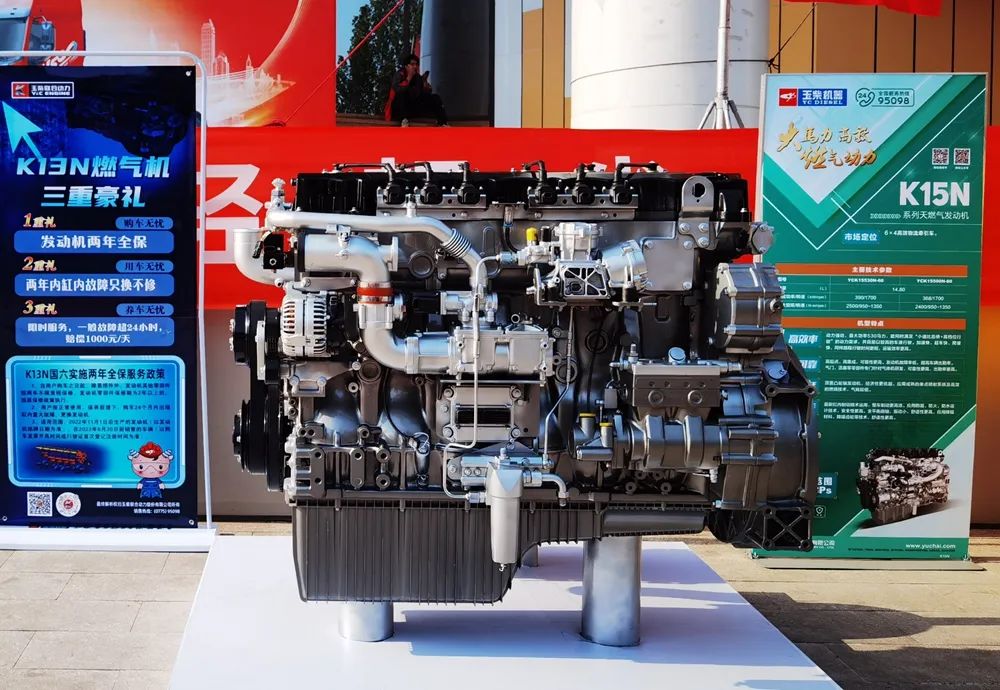

Why do mainstream heavy truck platforms in China all feature Yuchai K14N and K15N engines? Yuchai K14N and K15N engines are optimized based on the Yuchai K13N platform and their performance is further improved to meet the diverse operational requirements of customers.

In terms of power performance, Yuchai K15N has a maximum power of 570 horsepower and a maximum torque of 2,750 N•m., allowing for reduced gear operations during overtaking and climbing, without worry when driving, and ensuring smooth driving during starting, accelerations, and other conditions with the torque of 2400 Nm at low speeds of 800 rpm.

In terms of economic efficiency, with a minimum specific fuel consumption of 181g/kW.h, the engine offers a broader range of economical fuel consumption. With Yuchai's customized professional power transmission system, the gas consumption of the complete vehicle in comparison test is 2-3kg/100km lower than that of competing products.

In terms of reliability, the international supply chain accounts for more than 80%, and B10 service life exceeds 1.8 million kilometers. The application of Yuchai's patented cooling technology, EGR anti-icing design, valve torsion design, and cold start design significantly improves product reliability and extends service life.

In terms of comfort, active noise reduction techniques and advanced sound insulation materials in application lead to a noise reduction of 2.7-4.4 dB(A) compared to competitors.

In terms of lightweight design, structural design is adopted to apply lightweight materials such as aluminum castings, and the overall weight of the engine is the lightest in the industry.

In terms of safety, high-power in-cylinder brake and flame retardant materials for electrical systems are used, greatly improving customers' safety factors in use.

As an independent professional power system supplier, Yuchai will continue to leverage its industry-leading technological advantages to develop customized products according to customer requirements, aiming to create value for customers through power and assist them in achieving commercial success.